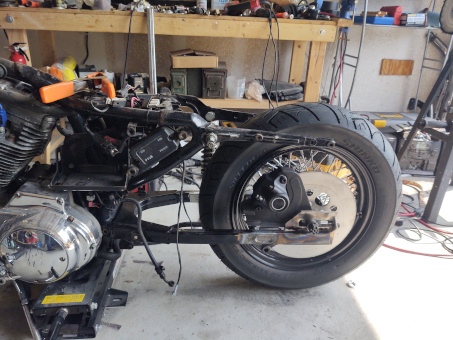

One of the things I wanted to do was to distract from the factory look of the bike. I started working on the rear assembly. I started cutting the rear swingarm down to get rid of the weak spot Sportsters tend to have right where the axle bolt fits through the swingarm assembly. I cut 3 inches of the end and cut 9 inches off of a donor unit. I double checked my measurements and cleaned everything up. Next I had to find an experienced welder. I found a guy that does welding professionally for military airplanes. He did an excellent job and made sure it was solid and safe. The rear wheel actually sits above the swing arm instead of inline. This gives me about 2 inches on height. Next I had a local independent shop powder coat it and I started assembling. The rear arm is 6 inches longer then the original. The shocks now mount on the bottom of the arm to help get that “low” look.

Now for the rear fender work……

The first pic shows me trying to reuse the original fender to no end. I ended up having to remove the original fender extensions to make room for a whole new fender assembly. It worked out better in the long run. I had wanted the hard tail look without the hard tail ride. I think I found it with this setup.

Progressive steps working on the fender. These three photos show how hard I had to

work to get the new unit to fit. Real Pain

This is what 3 months of fitting look’s

like. Mounting tabs, rear braces, and turn signals are in place and ready to move on, finally.